Protecting Multiple Boiler Systems

When a plant is running multiple boilers, operators need to act with vigilance. “Out of sight, out of mind” can be a ticket to an expensive boiler failure. It may be easy to ignore boilers that are not online, but it is important to monitor and protect boilers in standby or offline mode. A program applied to online boilers can do a great job while they are running. Offline boilers also demand attention. Your program of protection must include all boilers, in whatever state of operation they’re in. Here are some suggestions for protecting those boilers which are not firing demand.

Chemicals Can Stratify in Offline Boilers

You still must run tests on offline boilers: tests may not tell the whole story. It’s important to remember that when a boiler is idle, the chemistry in the boiler can stratify. The chemistry in the top of a boiler may not be the same as the chemistry in the bottom. This particularly pertains to sulfite. Testing may indicate a sulfite level in one part of the boiler that is quite different from the sulfite level in another section.

For the best protection, boilers should be fired up regularly to circulate the water. It’s not necessary to bring these standby boilers up to pressure, but they should be warmed, and the water should circulate. We recommend doing this weekly. Test before and after circulation and see what the test results show; it will prove what we are saying. Maintaining standby boilers in the control range is much easier than letting the levels get out of whack, and then trying to restore them to correct levels.

Options for Protecting Your Offline Boilers

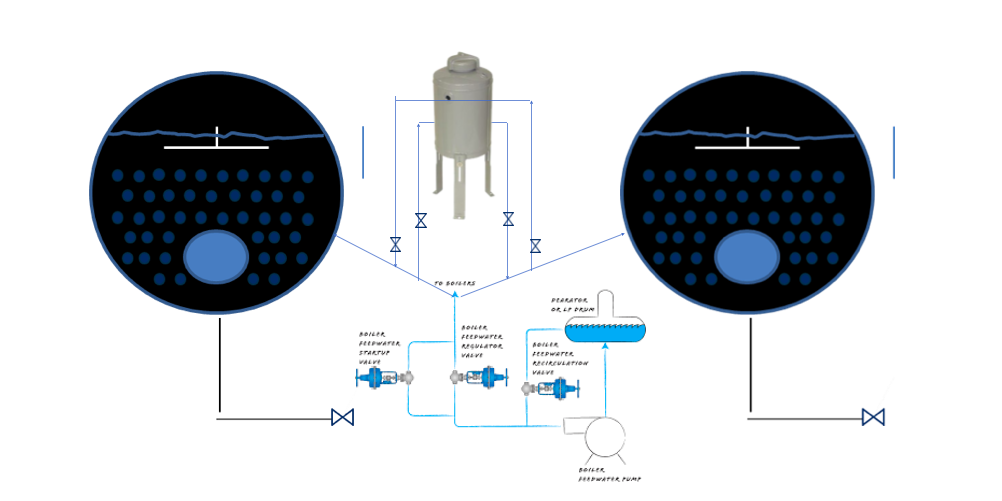

Installing a recirculation pump is a simple and convenient way to protect offline boilers. You must modify the piping so this pump can circulate the water while the boiler is offline. A sample point and pot feeder in this circulating line permits chemical adjustment. Obviously, you need to remember to isolate and turn this pump off when bringing the standby boiler back online.

Another option for adding chemicals to one boiler and not the entire system is to install a bypass pot feeder into the feed line. By directing through the feed water line going to a specific boiler, one feeder can allow chemicals to be added to one the boiler in need. Valving/piping can be reset and chemical and water is easily routed to the boiler in need.

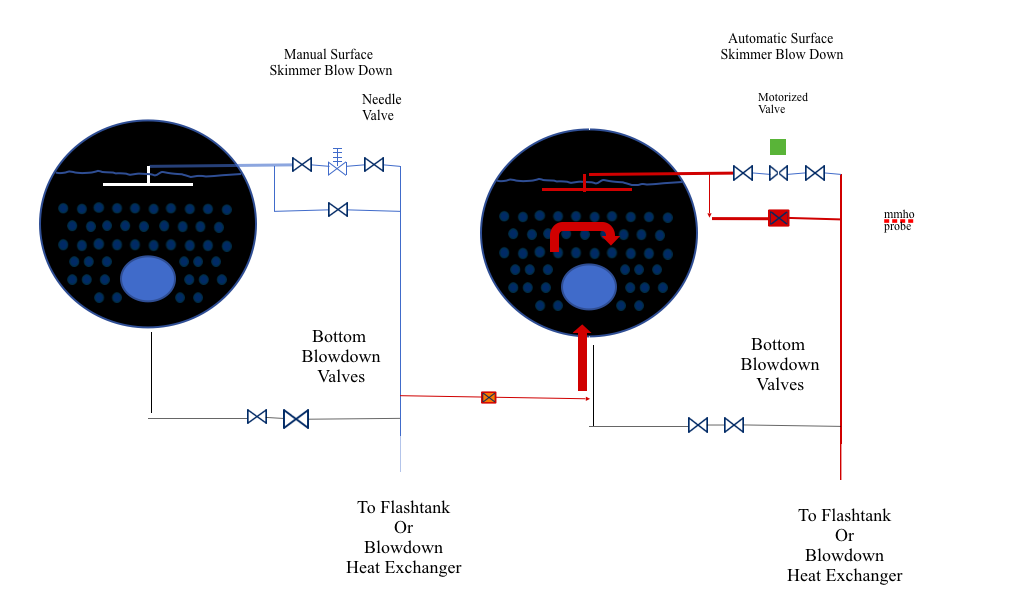

Lastly, a cascading surface blowdown piping configuration allows a plant to take the surface blowdown from the lead boiler and run it through standby boilers to maintain proper chemistry and keep them warm. Again, plumbing modifications will be needed, but this means that maintaining chemicals in the lead boiler will concurrently maintain correct chemistry in all boilers including those that are standing by.

Monitor and Protect All Boilers, Whether Online or Offline

Standby boilers can corrode, and they can fail if they are not properly maintained. Testing the lead boiler can be misleading. It may test well–at the same time the chemistry in the standby boiler may get progressively worse and corrosion can occur. Please spend the time and energy needed to protect the entire boiler plant. A year of great protection for online boilers can be disappointing if the standby boilers in the same room have been neglected.

Your Chemtex water treatment professional has the expertise to work through all aspects of your specific operational factors and help set your plant up for success in your ongoing efforts to protect all the plant boilers from the number one cause of boiler tube failure: Oxygen attack. Standby boilers often fall prey to this type of attack.

/NQA-ISO-9001-Logo-ANAB.jpg)