Corrosion Coupons: A Worthwhile Investment

Corrosion coupons are a good example of old-school technology that still earns a valid place in contemporary water treatment.

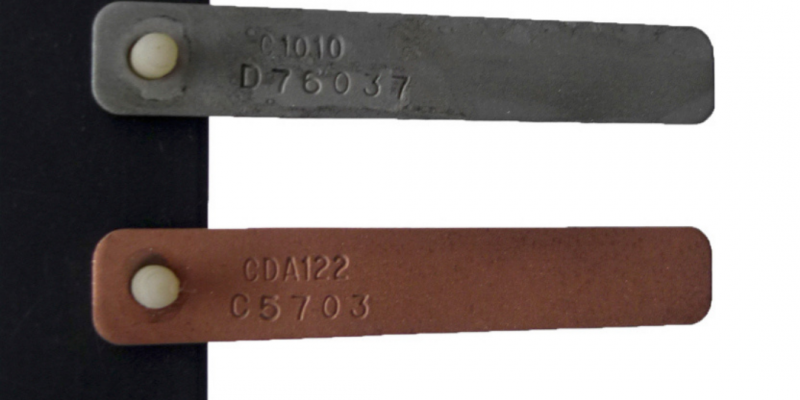

A corrosion coupon is a simple corrosion monitoring device. Corrosion coupons are strips of metal that match the metals in the system where they are installed. They are carefully measured, weighed and logged, then placed in the system for a prescribed time, usually about 100 days. After the test period elapses, they are removed and measured, weighed and logged again. The differences in the coupon before and after the test is meant to simulate the corrosion conditions in the system at the location where the coupon was placed.

The coupons are typically installed into a corrosion coupon rack or bypass. In cooling systems, the coupon rack can be equipped with clear PVC which enables operators a simple visual inspection of the coupon during the test period.

Why Use Corrosion Coupons?

Corrosion is one of the significant problems which proper water treatment effectively addresses. Identifying, reducing and preventing corrosion are critical to keeping equipment functioning properly as well as preserving equipment life cycle. Unchecked corrosion leads to system failure.

Corrosion coupons are a simple, non-intrusive, inexpensive, and accurate way to monitor the corrosivity of a system. The coupons are installed to replicate the corrosion rate experienced in piping, pipelines, or vessels. They can also be used to evaluate the effectiveness of the program in place.

Data derived from corrosion coupons can prove a program is functioning well. It can also help us and our customers evaluate alternate programs if better protection is needed.

Advantages of Monitoring with Corrosion Coupons:

- They are easy to install. A corrosion coupon rack is an inexpensive installation which allows feedback and confirmation of the existing water treatment program.

- It’s easy to match the metals in your system with corresponding metal coupons of mild steel, copper, stainless steel, etc.

- The coupons can be visually inspected.

- Deposit coupons and screens can help identify the scale of microbiological activity in the system.

Disadvantages of Monitoring with Corrosion Coupons:

- It takes time for corrosion to take place, so it does not provide instant feedback. The coupons are typically evaluated after 90-100 days, which allows sufficient time for barrier protections to form in the system.

- Corrosion coupons won’t reflect short-term changes. For example, if an excessively corrosive condition occurs for a short time, the coupons can’t pinpoint when it happened. Online corrosion monitors can provide this information.

- Corrosion coupons may not help identify problems in systems that involve many types of metal (aluminum, stainless steel, mild steel, copper and brass) in one system which are not separated by dielectric unions. A combination of different metals may cause galvanic corrosion. It occurs when two or more dissimilar metals are piped together and one is more noble than its neighbor. Corrosion coupons do not typically allow us to replicate all of this serious issue.

Establish a Corrosion Coupon Program with Chemtex

If you don’t have a corrosion coupon program in place, contact us at Chemtex. These programs require a relatively small investment, and can identify potentially costly corrosion issues so they can be addressed properly. When a program is performing well, corrosion coupons are an economical way to verify success.

/NQA-ISO-9001-Logo-ANAB.jpg)