Cooling Tower Controllers: Limitations and Connectivity

The ever-increasing automation in the water treatment field has radically transformed the industry for the better.

System bleed and chemical feed automation are both essential in this day and age, for reliable operation with minimal headaches.

They allow control to run based on user-defined programming, so things are nearly infinitely customizable. With the right options, they can provide control with varying parameters.

Automation means you can have dynamic control of your plant 24/7, versus the static control of the old days, when every evening departure and morning return had just a glimmer of trepidation.

And of course, automation has had a tremendous impact on time management, enabling plants to do far more with less staff, saving on personnel operations costs.

Benefits of Controller Connectivity

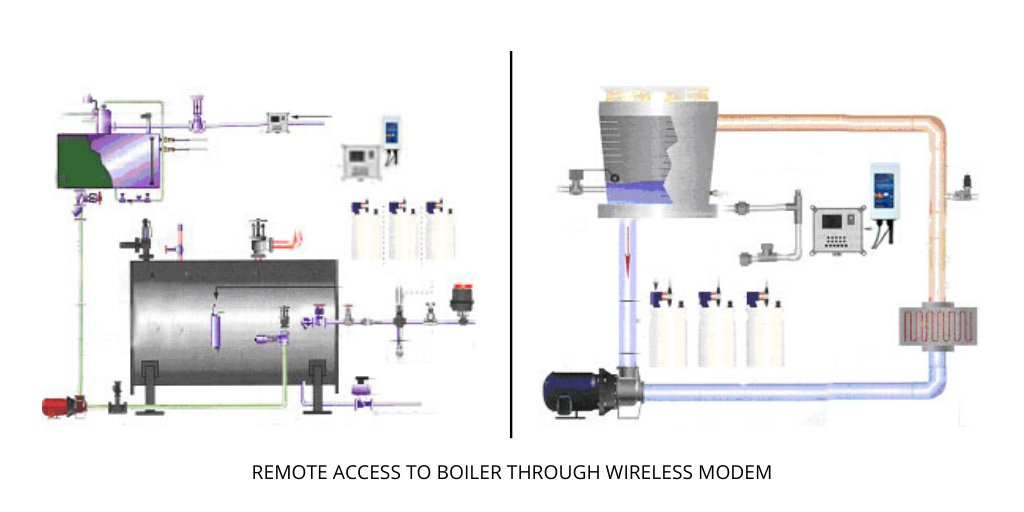

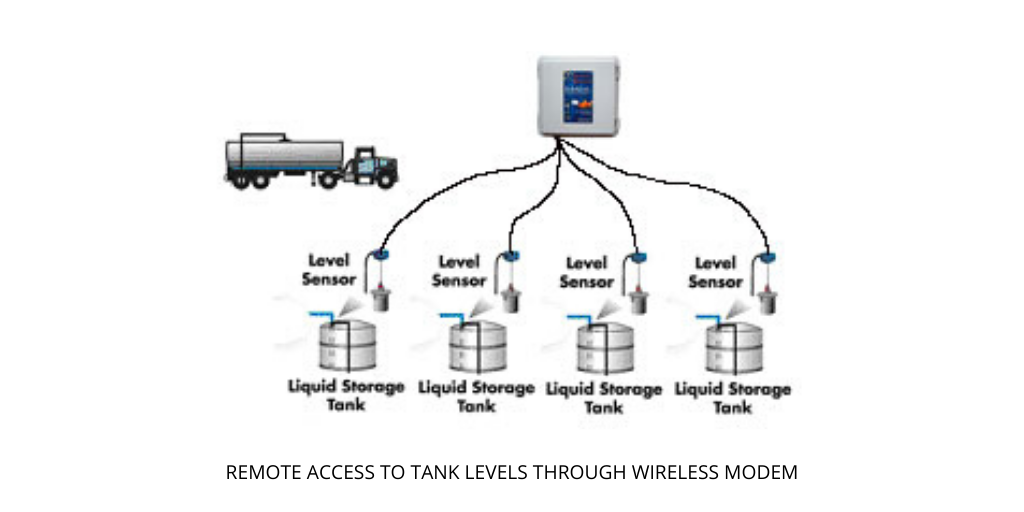

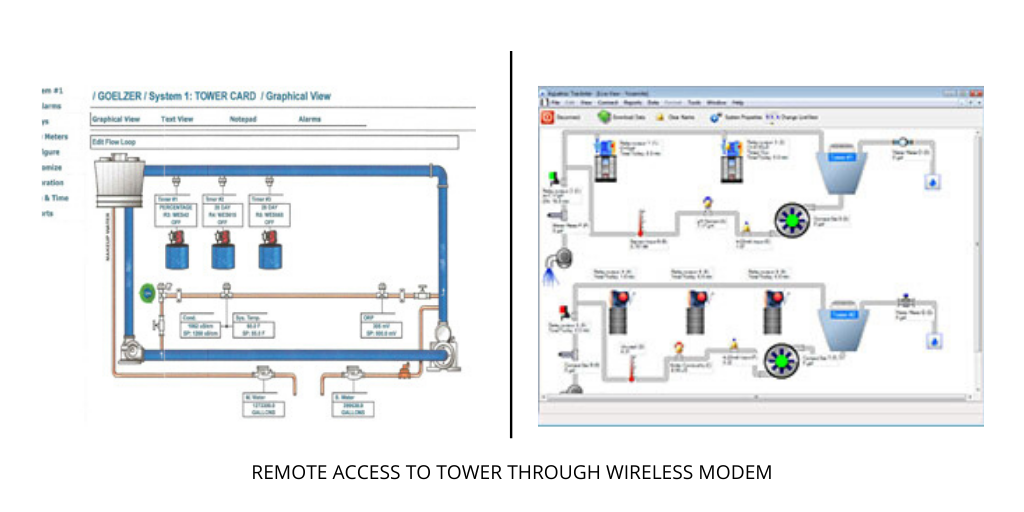

A connected controller, or remote access controller, offers the next generation of benefits. When you can access the controller remotely, you’ve got 24-hour access to all the essential tools it governs and data it gathers.

Benefits of a connected controller include:

- Allows users to monitor system operations in real time

- Allows email alerts about real time alarms

- Allows users to troubleshoot remotely

- Allows data management with historical perspectives

- Improves time management

A good connected controller relies on advanced encryption, ensuring that server integrity – and all your vital data – is not compromised. It doesn’t have to rely on the building management system – it can be set up relatively simply with a wireless connections.

Ultimately, the greatest benefit of a remote access controller is the great peace of mind it provides to the user.

Contact your Chemtex rep for a demo/quote to see how a “connected controller” can save you time, reduce stress, and reduce chemical, water and sewer costs.

/NQA-ISO-9001-Logo-ANAB.jpg)