Boiler Burner Tune-Ups – A Good Investment

At Chemtex, we focus on the water side of your boiler, emphasizing how to protect tubes from corrosion and scale; how to minimize blowdown; how to reduce water waste; and how to recover and reuse heat within the system.

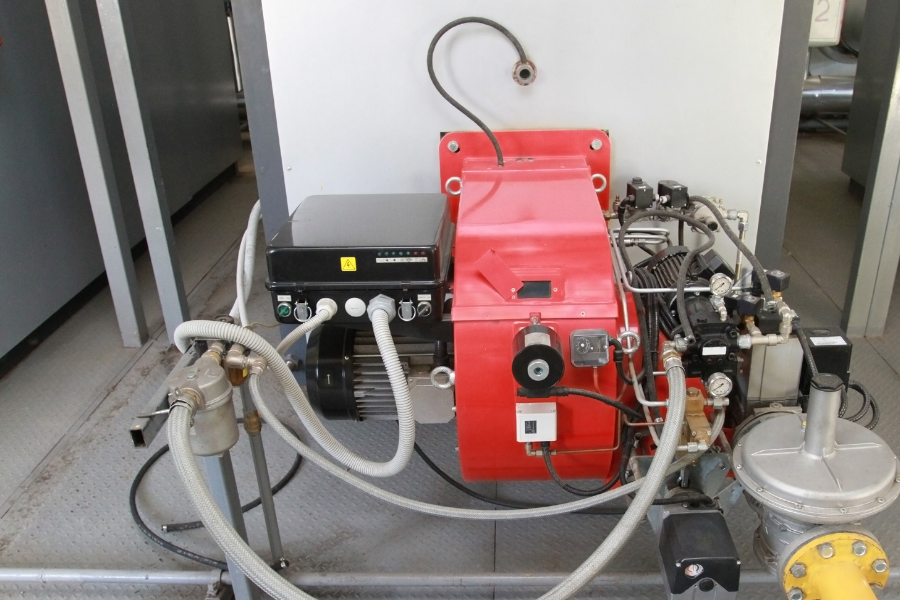

However, we want you to think about how to maximize efficiency on the burner side of the boiler as well. Inefficient fuel combustion can be extremely impactful. Today, most boilers burn natural gas, so that’s the fuel we’ll discuss here.

Because heat transference from the flame to water is not 100% efficient, each improvement to burner efficiency is amplified.

Oxygen and Carbon Dioxide Quantities

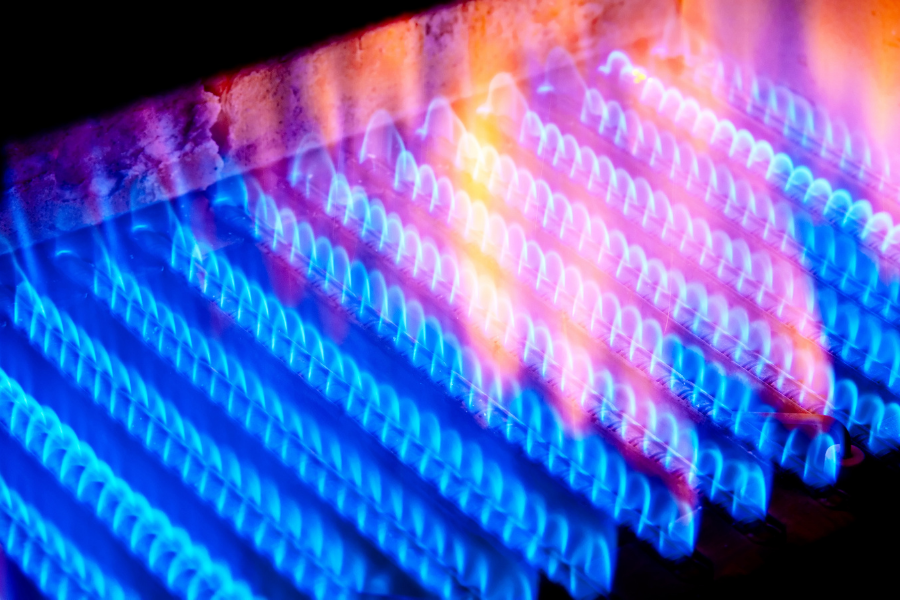

Measuring oxygen and carbon dioxide in the exiting combustion product is a useful tool for optimizing burner combustion of fuel. Excess oxygen leaving the boiler means fuel has not been burned properly. However, if insufficient oxygen is leaving the boiler, this may result in soot building up on the fireside, which further impedes heat transfer.

Are you running the boiler on standby fuel (fuel oil)? Make regular efforts to be certain that the burner has been tuned up using both the primary and the standby fuel. If the boiler has gone to standby fuel, it’s likely that there are extreme circumstances: Variations and costs from improper tune-up will be exaggerated.

Boiler Burner Tune-Ups Pay for Themselves

A boiler burner tune-up will cost around $300-$500 per boiler. Let’s assume you gain a potential savings of 1% with a proper boiler tune-up. Let’s also say your plant is running a 150 HP boiler, at an annual fuel cost of $100,000. That 1% savings on fuel amounts to $1,000: That’s less than a 6-month ROI.

Variations in Boiler Operation

Boiler burner tune-ups help mitigate the impact of seasonal changes. Shifts in temperature, barometric pressure, and fuel BTU value may negatively impact the combustion process, leading to increased fuel costs.

Air temperature and barometric pressure also affect air density, which refers to the number of oxygen molecules per cubic foot. In other words, the combustion air fan will deliver the same number of cubic feet to the burner, but the number of oxygen molecules will be higher or lower.

The BTU value of fuel will change based on the amount of carbon it contains. While the gas regulator passes a consistent scfh (standard cubic feet per hour) of fuel to the burner, the number of carbon molecules will depend on the fuel’s BTU value. Ultimately, this will change the level of excess air in the stack gases and affect the burner efficiency

Improper combustion caused by seasonal changes can be identified by increased stack temperature. This may be caused by a high volume of excess air which carries heat out of the stack, or by deposits of soot and other non-combustible material which interfere with heat transfer. A properly combusting burner should result in the fuel gas registering approximately 50-100 degrees over the saturated temperature in the boiler.

The point is, burners can get out of calibration and burner efficiency and fuel combustion can change with normal operation. Tracking variables related to the burner is a simple tool that can be critical to good boiler operational maintenance. The boiler log should include recording the stack temperature baseline with a clean, well-tuned boiler. Consistently maintaining the log will help you identify changing conditions influenced by any one of a multitude of factors.

Experienced Boiler Tune-Up Assistance

If you don’t have a qualified tech on staff, please enlist your Chemtex water treatment professional to help find a skilled contractor who can tune your boiler up properly. For some quick tips on boiler burner tune-ups to improve efficiency, reduce pollution and save money, check out this guide from Energy Star.

You can also consult articles from Cleaver Brooks, a boiler room systems solution provider. You can access past webinars and content about boiler maintenance and operations on their website.

/NQA-ISO-9001-Logo-ANAB.jpg)