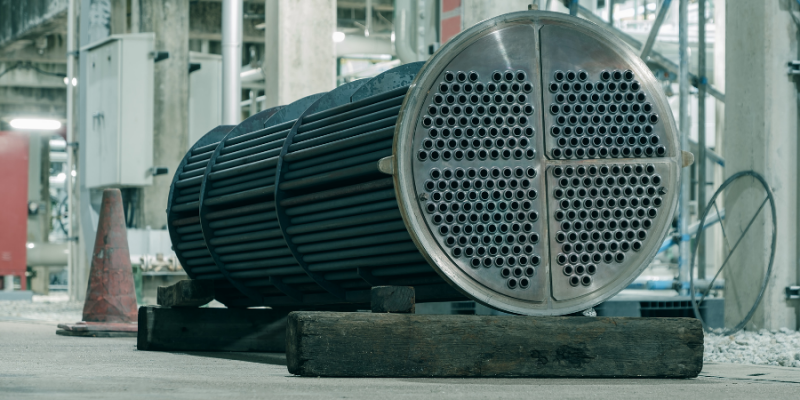

Coating Options for End Bells and Tube Sheets

Coating bare metal is a universally employed method to minimize corrosion and keep it protected and intact.

The end bells and tube sheets in a heat exchanger are prone to corrosion, water is often sits idle and the sections of a tube sheet can collect debris in the system. Over the years Belzona has been used to protect these sections of chillers. Belzona is an excellent multifunctional material which can protect and reinforce metal, but preparation of surfaces is not easy. Belzona will only adhere to sandblasted bare metal. This makes it a costly and time-consuming process.

Omnithane Offers Good Protection

Recently, we have started using another material to protect metals subject to the conditions in a chiller. We have used it with great success.

Omnithane is a single component, moisture-cured resin. It contains a proprietary blend of micaceous iron oxide and zinc to function as a primer which is field and shop friendly. It may be used in OEM manufacturing, potable water, and wastewater immersion. And it may.be used for marginally prepared rusty steel. We really like it.

Benefits of Omnithane

- It is designed for underwater applications

- It is reasonable priced

- It requires far less surface preparation, no sand blasting

- It has excellent adherence properties; it does not shed off and cause problems.

- If there are areas where rust has broken through, it is easy to go back and touch-up a spot.

Our Advice

Check your cooling water box for old corrosion. If you find some, and you think a treatment applied to the surface will help protect the system from further damage, consider using Omnithane as a protective coating. Let us know what you think!

At Chemtex, we really value our dialogue with you folks out in the trenches, so we’re always interested in your experiences. Contact us with any questions you might have, we’d be happy to help.

/NQA-ISO-9001-Logo-ANAB.jpg)